About Our Manufacturing Excellence

Leading the Industry in Plastic Fuse Holder Production

Our manufacturing facility in Malaysia stands as a testament to precision engineering and unwavering commitment to quality. We have established ourselves as a premier producer of plastic fuse holders, serving diverse industries across the globe with reliable electrical components that meet the highest international standards.

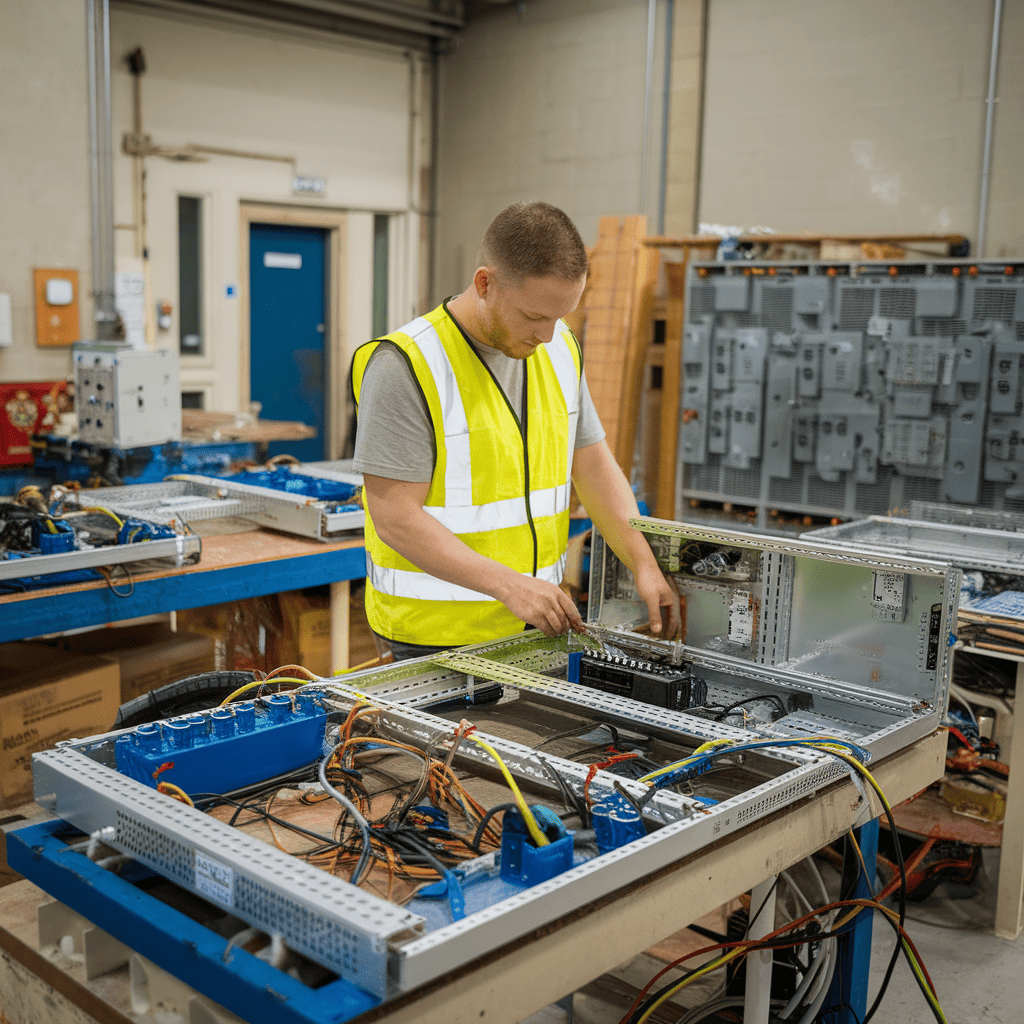

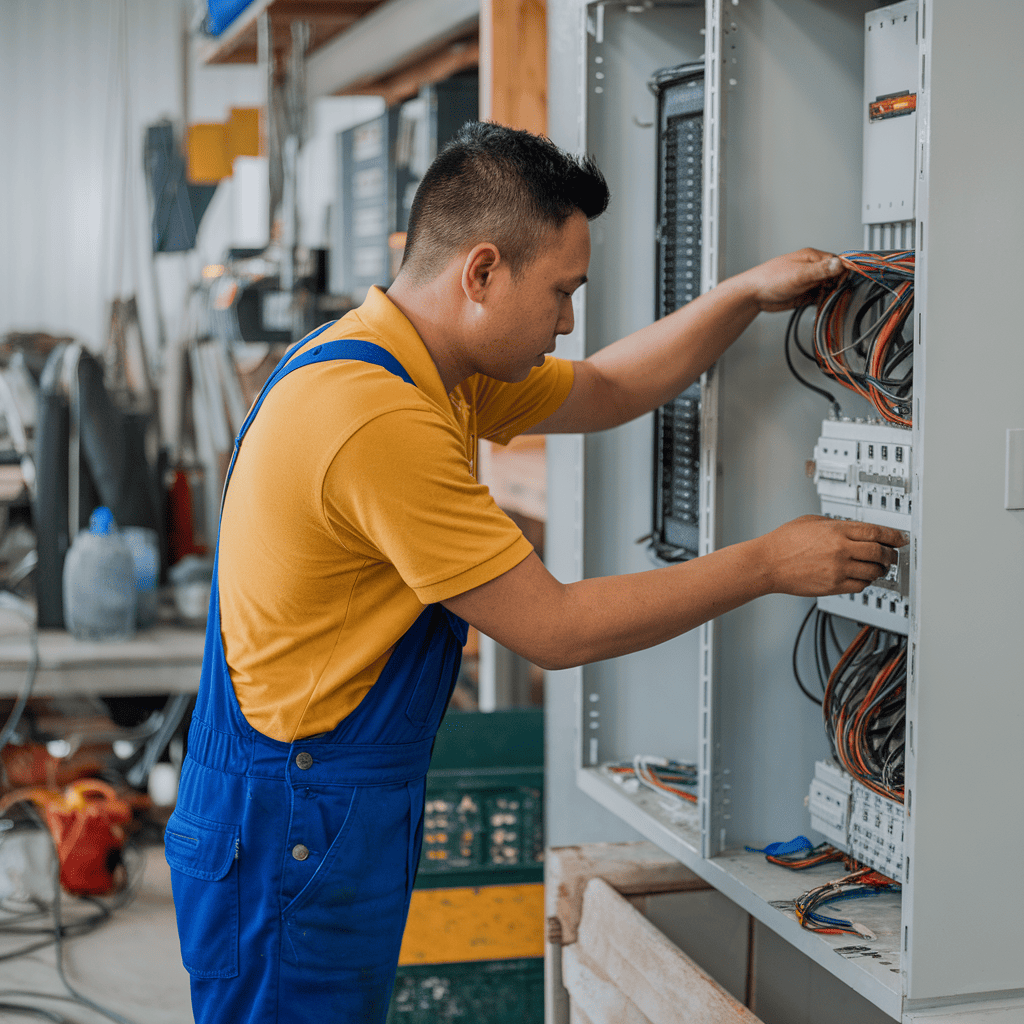

With years of experience in the electrical components manufacturing sector, we have developed comprehensive expertise in creating durable, efficient, and cost-effective solutions for fuse protection systems. Our team of skilled engineers and production specialists work tirelessly to ensure that every product leaving our facility exceeds customer expectations.

The cornerstone of our operation lies in our state-of-the-art production capabilities. We utilize advanced manufacturing technologies and rigorous quality control processes to guarantee consistent performance across all our product lines. Each fuse holder undergoes meticulous inspection and testing before being approved for shipment to our valued customers.

What sets us apart in this competitive market is our dedication to continuous improvement and innovation. We regularly invest in new equipment, training programs for our staff, and research into emerging materials and manufacturing techniques. This proactive approach enables us to stay ahead of industry trends and provide cutting-edge solutions that address the evolving needs of modern electrical systems.

Our commitment extends beyond mere production. We understand that successful business partnerships require transparent communication, reliable delivery schedules, and responsive customer support. That's why we maintain a dedicated team ready to assist with technical inquiries, custom specifications, and after-sales service. Building long-term relationships with our clients is not just a goal—it's the foundation of everything we do.